Carton Flow Rack – Stability in a Shifting E-Commerce World

SOLUTIONS

FOR THE TOUGHEST APPLICATIONS

"*" indicates required fields

Carton Flow Rack Delivers the Goods for E-Commerce SKU Selection

Did you feel that? It was a cataclysmic shift in purchasing. Everyone knows that the digital age has ushered in the phenomena of e-commerce buying, and the supply chain has been adapting to meet demand, but in March of 2020 everything changed. “The coronavirus is the biggest disruption to consumer retail spending patterns in recent history, far eclipsing the dramatic events of 2008’s Great Recession.“ eMarketer reports.

The global e-commerce sales projections are upwards of 4.5 trillion by 2021, which represents a threefold increase in just 7 years and with no sign of stopping. With more platforms to facilitate an e-commerce purchase, i.e. mobile, voice assistants, social media “buy” buttons, etc., we not only need to expect massive growth, but we need to prepare.

Meeting Customer Expectations

The bar is high. Because purchasing is no longer limited to geographic location, competition is fierce, and that means the downward pressure on the supply chain is mounting to deliver the right product at the right price and in the shortest amount of time. That’s a lot of pressure, but there are warehouse tools that can help you deliver.

If we hone in on e-commerce fulfillment, we see where we can shave valuable time and costs all while improving the customer experience.

Carton flow rack is a product whose time has really come. Not that carton flow hasn’t always been valuable, but now with the laser focus on small order fulfillment, there’s even more reason to create or convert pick areas with carton flow.

Cart-Trak Carton Flow with Tilt Tray

Carton Flow Rack Benefits:

- Space-saving – increase up to 60% vs static rack and shelving

- Condense storage footprint saves upwards of 20% floor space

- More pick locations – up to 40 locations per bay

- Labor savings of up to 75% vs static rack by reducing motion and travel

- Improve pick accuracy for higher customer satisfaction and low returns

- Increase productivity by consolidating and organizing SKUs

Carton flow rack is created with low-profile, gravity-flow rails set on a slope into standard storage rack to convert it from pallet storage to small-item storage. Choose between wheeled and roller carton flow, depending on inventory specs. Inventory can refer to full cases, totes, or individual items that are organized by SKU lane for faster load and pick.

Inventory is loaded in the rear of the system and flows down to be picked from the front. The design automatically rotates stock, minimizes congestion in the pick area, and generates automatic pick face replenishment, so no downtime waiting for re-stocking. Because the SKU lanes are organized and separate, picks are faster and more accurate. Carton flow rack is also compatible with automated picking solutions such as pick-to-light systems that further enhance order picking productivity.

The pick area can be designed as standalone or as part of a pick module that combines carton flow with pallet storage rack and conveyors. A pick module creates efficient high-volume case picking by consolidating a large number of SKUs in a compact footprint to minimize travel and maximize productivity. Pick modules can increase SKU capacity by up to 50%. Mobile carton flow is also available for small parts packaging and seasonal or fluctuating SKU needs.

Designing Carton Flow Rack for Optimal Performance

Carton flow is beneficial and easy to use, but to attain all the benefits of this system, it should be designed in particular to your order-picking process and inventory specs.

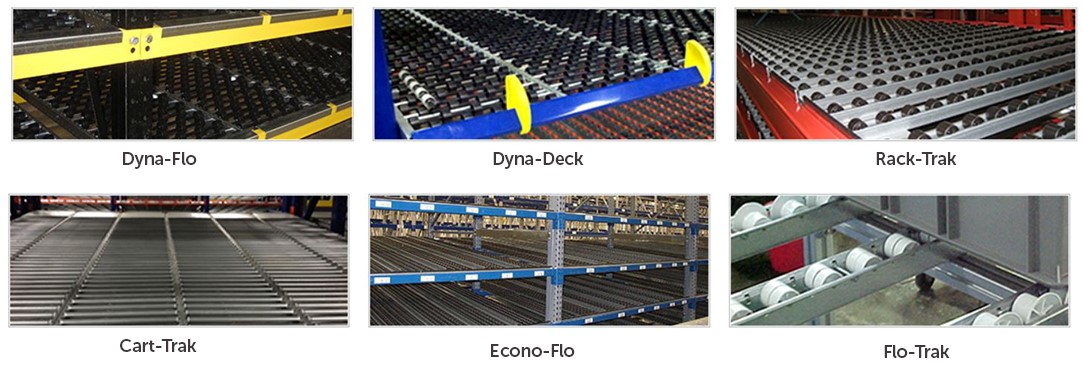

Mallard offers several options of both wheeled and roller carton flow to meet all inventory and operational needs. Typically, roller rails like our Cart-Trak are best for same-size inventory as the roller width is chosen to closely match the width of the inventory. On the other hand, wheeled carton flow like Dyna-Flo allows differently sized and shaped inventory to be positioned side by side all within the same bay. Snap-on dividers and/or lane guides can be added for faster visual lane identification and to segregate products if necessary to meet safety guidelines.

Mallard’s full-wheel bed design takes advantage of every inch that the rack bay has to offer to allow for more SKUs. Typically, 20% more storage can be created with wheeled vs roller lanes; however, again it is contingent upon inventory specs.

We offer Dyna-Flo HD (heavy-duty) carton flow that supports 50 lb. sq. ft. capacity per 8 ft. unsupported length. We also offer Flo-Guide for inventory that requires lane guidance.

To enhance the use of carton flow rack and ensure you are maximizing efficiency, add-on accessories can be added to your system, no matter which type of system you choose.

Mallard Carton Flow Accessories

- Tilt tray – galvanized steel trays can be set at any pitch to reduce worker bending and reaching

- Impact tray – heavy-duty galvanized steel tray absorbs the impact of heavy cases and inventory being loaded into the carton flow lane. Reduces wear and tear on the wheels and rollers.

- Snap-on entry guide – quick SKU reprofiling and lane separation with our tall, visible guides

- Lane divider – full-length dividers fit quickly into place to provide SKU separation down the full lane

- Specialty mounting bracket – recessed on front and rear beams to be compatible with RFID, pick-to-light and pick-to-voice operations for both put-away and pick operations.

The Mallard team is committed to designing your carton flow system for optimized performance. No one knows carton flow like the gravity flow experts at Mallard… and not only that, we offer free in-house testing of your carton flow system before purchase so we can be assured that your system is perfectly designed for your needs. Call today to speak with our team about the challenges you are facing with e-commerce demand or other warehousing and distribution order processing pressures.