Carton Flow Rack – What Is A Beam Tie & When Do We Use It? | Mallard Best Practices

SOLUTIONS

FOR THE TOUGHEST APPLICATIONS

"*" indicates required fields

A little overloaded these days? Well, overloading can lead to a lack of productivity, and honestly, who needs that? Enter Mallard Best Practices with tips to help your gravity flow systems perform even under pressure. Let’s take a look at a recent carton flow rack application that provides a good example of what happens with system overload… but don’t worry, there’s a solution and, of course, good advice for prevention.

Carton Flow Rack Overload Risks

- Beam deflection

- Lane shifting

- Improper flow

- Rails dislodging

The Why?

A Dyna-Flo carton flow system, like any other gravity flow or storage rack system, is designed from the rack up based upon certain inventory specs. When that inventory changes, the system may be able to accommodate the new inventory, or it may need some updates. When the weight increases, it is important to make sure that your team is not exceeding capacity limits. It’s a matter of function and warehouse safety.

When this scenario happened recently for a customer, we found that the excessive weight was causing the beams to deflect outward and even twist a bit which was affecting the effectiveness of the carton flow lanes. Once we identified the why… we needed to establish a fix.

Beam Ties – The Link to System Capacity Demand

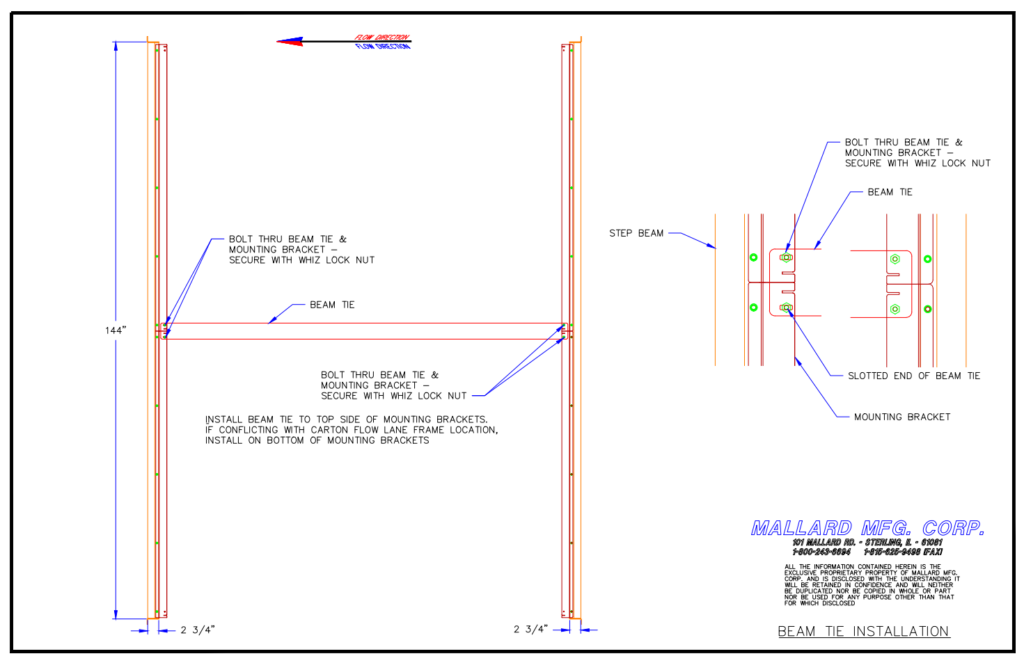

Beam ties are steel rack supports that run parallel to the carton flow lanes and are secured to the front and rear beams. They can be retrofitted to existing systems to improve system stability and increase capacity while also preventing beam deflection.

This customer had two bay widths measuring 144” & 72” wide, all 102” deep within the carton flow rack. As you can see from the drawing above, the 96” long beam ties were installed front to back, attached to the step beams with mounting brackets to provide the stability needed to prevent the beams from bowing out and/or twisting under the extra carton weight.

Carton Flow Rack Design Cautions & Notes

Beam measurements and materials will have an impact on the success of your carton flow system. Ensuring your beams are the proper size to handle the anticipated system capacity is vital to system effectiveness and, of course, productive operation.

Additionally, we do offer Dyna-Flo HD for heavy-duty applications. If you anticipate inventory changes or are close to the upper end of load capacity for a standard system, consider Dyna-Flo HD to give you the room to handle potential carton weight increases. Dyna-Flo HD is rated for 50 lbs. per sq. ft. capacity per 8’ unsupported length. It is also manufactured with higher side rails to eliminate the interior support beam and enable added shelf capacity while also creating more vertical clearance between shelf beams.

How Can We Help Keep Things Flowing?

How Can We Help Keep Things Flowing?

If you are experiencing gravity flow challenges or other warehouse storage and picking challenges, give the Mallard team a call. We are gravity flow rack experts, but most importantly, we’re problem solvers.

Also, check out our other Mallard Best Practices blogs for practical solutions to pallet flow and carton flow performance and installation questions.