Customers Give New LIFO to Carton Flow to Control SKU Proliferation

SOLUTIONS

FOR THE TOUGHEST APPLICATIONS

"*" indicates required fields

As warehouse operators deal with SKU proliferation and challenging picking strategies for slow-moving products, space constraints and efficiency become bigger concerns. Well, don’t start knocking down walls just yet; there is a readily available solution if you’re just willing to roll with it… It is a single-aisle access push-back carton flow.

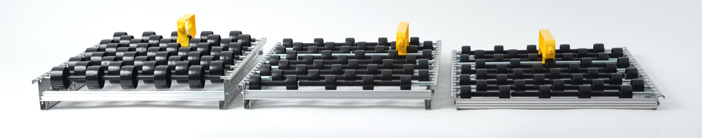

In this configuration, the carton flow shelf is accessed via a single aisle for both picking and replenishment, potentially doubling SKU volume by removing aisles, while keeping all cartons within easy reach. Smooth-rolling carton flow tracks allow workers to easily push back cartons, making this “carton flow in reverse” an excellent LIFO option for shallow depth applications, particularly for slow-moving SKUs.

We recently used this strategy for a customer with an existing back-to-back 42” deep selective pallet rack. By converting lower levels to push-back carton flow they easily gained needed pick locations and created an ergonomic, productive picking solution for order selectors.

So why not just install a simple wire deck or other shelving accessories you may ask? Well, bang for your buck, carton flow has several advantages that make it a better solution…

LIFO Carton Flow Advantages:

- Ergonomic solution for both picking and loading

- Front to back incline eases “push-back” loading

- Rollers automatically replenish the front position when picked

- Increase picking accuracy – neat, clean lanes keep SKUs separated

- Double pick face quantity and increase cube density

- Lane guides & dividers enhance picking ease

With flow guides or lane dividers, you help keep lanes visually organized for both picking and loading which increases ease and accuracy for employees. Full or partial lane dividers are available and are both easy to install to accommodate SKU changes. Watch our video to see how easy it is to install and move.

With flow guides or lane dividers, you help keep lanes visually organized for both picking and loading which increases ease and accuracy for employees. Full or partial lane dividers are available and are both easy to install to accommodate SKU changes. Watch our video to see how easy it is to install and move.

If you’ve been following us at all, you know we love a good storage challenge and creating custom gravity flow solutions that optimize space and efficiency for our clients. If you have an interesting project challenge or unique gravity flow application, let us know – we’d be happy to discuss your vision and perhaps use the feature in a future blog. Just give us a call!