Counting Down the Days to RILA 2018 Retail Supply Chain Conference

SOLUTIONS

FOR THE TOUGHEST APPLICATIONS

"*" indicates required fields

The Mallard team is hitting the road for the first industry show of 2018 – The RILA Supply Chain Conference in Phoenix, AZ. We’ll be in Booth #844 showcasing carton flow and pallet flow solutions that delivery space-saving, cost-effective storage efficiency to retail distribution.

The Mallard team is hitting the road for the first industry show of 2018 – The RILA Supply Chain Conference in Phoenix, AZ. We’ll be in Booth #844 showcasing carton flow and pallet flow solutions that delivery space-saving, cost-effective storage efficiency to retail distribution.

Industry shows, like RILA, give us the chance to speak with supply chain professionals and to hear the challenges as well as the success stories in overcoming storage and fulfillment demands.

The common thread of retail warehousing is multi-level volume storage, with fast, accurate order fulfillment. Custom designed gravity flow like, pallet flow and carton flow are simple to use with low maintenance and operational costs. Gravity flow systems can work with automated picking systems and are uniquely designed for efficient SKU slotting and ergonomic order selection.

So what kind of systems are we talking about? Here ‘s a quick overview of some Mallard gravity flow solutions for retail warehousing needs…

Gravity Flow for Retail

Gravity Flow for Retail

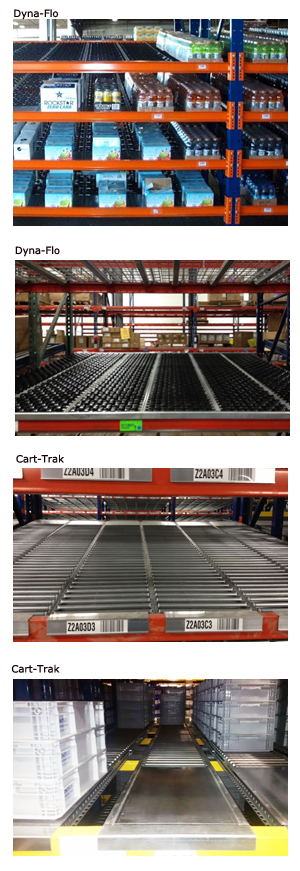

Carton Flow Rack

- Full carton, tote and each-pick fulfillment system designs available

- Several styles of carton flow meet your inventory needs – both wheeled and roller

- Full-line of accessories to protect your inventory, workers and carton flow system; as well as, increase picking efficiency

Pallet Flow Rack

- High-volume case-pick applications

- Layer-pick systems for mixed pallet orders

- Pallet staging for outbound full pallet orders

- Several wheeled and roller system options to choose from – customizable to meet your needs

- Full-line of accessories to increase the effectiveness of your pallet flow rack system and improve worker safety and efficiency

- Combining carton flow, pallet flow and/or selective pallet rack for carton, tote and each-pick order selection.

- Orders can be picked to conveyor designed within the module.

Gravity Flow for E-Commerce

If you are an E-Commerce center, consider gravity flow for your Direct Order Fulfillment operations. Here’s why:

Fulfilling orders directly from a warehouse, particularly for the booming e-commerce market, requires that the retailer rely on their distribution network to pick the order as precisely as if the consumer had hand-selected it off the shelf themselves. Returns are very costly both in monetary terms and customer loyalty, so order accuracy is a must. Mallard’s diverse and flexible line of carton flow products are designed to help optimize your order picking operation whether your challenge is varied carton sizes, seasonally changing SKUs, faster pick and restocking needs, etc. And, all Mallard products are manufactured to last in busy warehouse operations.

How Carton Flow Optimizes Retail Fulfillment

- Improve productivity – quicker, more accurate picking with cartons automatically replenished at aisle face

- Gain 50% more storage, fewer aisles & 40 more pick locations vs selective rack

- Decrease labor costs – Save up to 75% in labor

- Maintain efficient FIFO inventory rotation

- Ergonomic, safe, order selection – easy access to all SKUs

- Save energy and lighting in condensed space

Combine your carton flow with pallet flow or selective rack for a Pick Module when you have a considerable amount of small-order and piece-pick order picking. Pick modules consolidate SKUs in a small warehouse footprint increasing SKU capacity by up to 50%. Within the pick module design, you also see increased load and pick efficiency and reduced picker travel times. A pick module typically includes carton flow in a forward pick area, or integrated within a multi-level pick module, with high-speed conveyance for quick order throughput.

Combine your carton flow with pallet flow or selective rack for a Pick Module when you have a considerable amount of small-order and piece-pick order picking. Pick modules consolidate SKUs in a small warehouse footprint increasing SKU capacity by up to 50%. Within the pick module design, you also see increased load and pick efficiency and reduced picker travel times. A pick module typically includes carton flow in a forward pick area, or integrated within a multi-level pick module, with high-speed conveyance for quick order throughput.

Replacement Carton Flow

If you are already using carton flow, but its looking a little worse for wear… Mallard has your quick, easy solution! Our Dyna-Deck carton flow rack is an affordable, drop-in replacement carton flow repair system for inferior, damaged case flow rails and wheels. Dyna-Deck provides full wheel coverage for all carton sizes and shape.

Pallet Flow for Case-Picking

Pallet Flow for Case-Picking

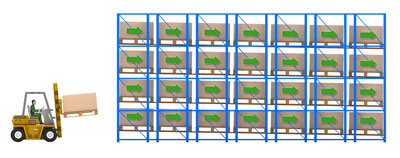

Full pallet reserve storage for high-volume, case-pick applications can be supplied by pallet flow rack within a pick module, or in stand-alone systems. Pallet flow separators allow for safe order selection and removal of the front pallet without rear pallet forces. Once the front pallet is empty it is easily removed, and the separator is reset with a simple hand or foot release which allows the rear pallets to advance.

Pallet Flow for Warehouse to Retail Fulfillment

Fulfilling orders directly to retail locations from the warehouse or DC may require a different fulfillment approach for storing a large quantity of pallets of the same SKU. Pallet flow racking optimizes space with a deep-lane capacity while still providing easy access to all pallets from the pick face. Space optimization also means increased productivity and less travel time for load and pick.

In addition, floor-mounted pallet flow in dock staging areas for full, single SKU and/or mixed pallets provides easy to access and accurate loading to awaiting trucks.

How Pallet Flow Rack Optimizes Retail Fulfillment

How Pallet Flow Rack Optimizes Retail Fulfillment

- Space optimization – double the storage capacity in the same footprint

- Efficient storage of high volume/low SKU products

- Increased productivity with less travel time to load and unload

- Ideal for high-volume, case-pick applications – manual case selection from the front pallet position with reserve pallet positions in queue behind

The Mallard team is looking forward to talking with you about your warehousing challenges. Be sure to look us up in Booth #844 at RILA or reach out to us by phone or email today!

(800) 243-6694 (USA only)

(815) 624-9491

or info@mallardmfg.com