Are Craft Brews Exploding… Your Operating Costs?

SOLUTIONS

FOR THE TOUGHEST APPLICATIONS

"*" indicates required fields

Mallard Keg Flow Reins & Tames Craft Brew SKU Proliferation

The craft brew headline of 2018 isn’t “SKU Proliferation” … believe it or not. In all honesty, we’ve already been living that reality for almost a decade. The real news is that Mallard has a gravity flow solution to help solve the beer distribution and warehousing challenges that have come with that SKU explosion. Keg flow provides a way to rein-in and optimize keg storage and handling, freeing up valuable cold store space plus gaining put-away and picking efficiencies that are lost in overcrowded warehousing space.

Keg flow accommodates kegs of all shapes and sizes in a condensed, multi-level gravity fed storage system that can be set up for EITHER FIFO or FILO inventory rotation.

- FILO (first-in/last-out) storage only requires a single aisle access to the system. Load and pick is done from one aisle in a “push-back-type” scenario.

- FIFO (first-in/first-out) storage requires separate load and pick aisles but helps significantly to minimize aisle traffic. It is the ideal solution for non-pasteurized, date-sensitive inventory.

Either way you choose, the deep-lane, condensed nature of the system saves valuable cubic storage space over static rack and provides the best option for fast, accurate order selection.

See Keg Flow in Action:

Keg flow is built to last in busy warehouse conditions and to continue operating day in and day out in cold store temperatures. Keg flow only needs to harness gravity to efficiently move your inventory. No need for electricity or expensive batteries to keep this system working. Easy to use, low maintenance and economical… but that is not all!

Keg Flow Benefits:

|

|

Designing Your Customized Keg Flow System

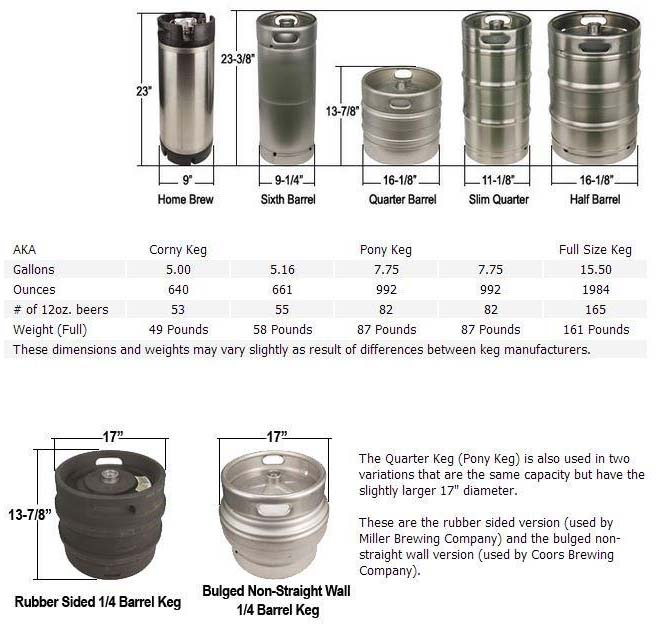

Keg flow easy to operate and maintain but Mallard also makes it easy to order keg flow. We’ve even included this handy keg size chart to help!

Here’s what we need to know in order to design a unique system just for your specific inventory:

-

- What types & size of kegs do you store? See chart (below) to help identify keg specs.

- What are the average quantities of each keg size? Include min/max inventory quantity for each SKU and allow for growth in SKUs where expected.

- Which roller sizes should you use? Mallard recommends durable 1.9” diameter rollers with hex axles vs 1 3/8” rollers. Larger diameter rollers with hex axles provide greater capacity and long-term durability.

- Do you require galvanized finish on the rack? Galvanized pallet rack is often recommended for storing products in exposed environments – outdoors, freezer and cooler rooms for example.

- What is the required depth per lane? Using the data gathered in #1 & #2 the lane depth can be determined (#of kegs per lane).

- What type of racking will the keg flow be attached to? This is an important distinction but not to worry because Mallard offers several different attachment brackets for both roll-formed and structural rack to ensure the most secure fit.

- How many levels of keg flow would best suit your needs? If your system will be hand-picked and loaded, the height of the lanes will be an important determinant for efficient, ergonomic order selection – if levels are too high or too low it can result in a lag in productivity or worker injury.

- How will you handle replenishment storage for your keg flow system? Depending on available space and inventory mix you can choose from several options for reserve storage and selection. For example, using selective pallet rack is an option for kegs stored on pallets providing optimal SKU selectivity.

It’s time to make this market explosion work FOR you as opposed to AGAINST you! Call our gravity flow team and let keg flow tame your warehouse chaos… it is the economical solution you’ve been looking for.