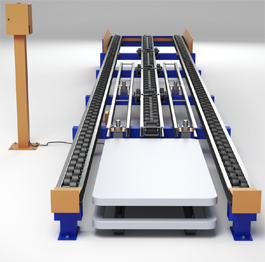

Ergo Cell Pallet Lift Table Improves Case Pick Safety & Ergonomics

SOLUTIONS

FOR THE TOUGHEST APPLICATIONS

"*" indicates required fields

Reduce Worker Injury & Save Labor Costs with Mallard’s Ergo Cell with Pallet Lift Table

As you probably know all too well, warehouse labor costs can account for up to 65% of distribution center operating budgets and are often the most difficult to manage due to injuries, workman’s compensation claims, and productivity losses. In 2012 alone, there were almost 3 million workplace injuries reported in the US, resulting in compensation claims, lost time, and lost productivity. Traditional order-picking techniques – repetitive bending, stretching, and straining to pick cases from the floor level or up into pallet rack, account for a large majority of these injuries in the warehouse. See the Ergo Cell pallet separator in action.

In addition, warehouse and distribution center operators are under mounting pressure to control and reduce costs, increase pick rates, and improve customer satisfaction. Mallard’s Ergo Cell pneumatic pop-up pallet separator can help! Ergo-Cell pallet separator pairs with an ergonomic pallet lift table embedded into your pallet flow lane for case-picking applications. Pneumatic controls elevate the front pallet on the lift table, creating a comfortable range of motion for order selection, preventing repetitive injuries, and improving picking rates. Operators can easily remove empty pallets from the lift table with the weight or pressure of subsequent pallets.

Advantages:

- Supports ergonomic case picking

- Eliminates back pressure of rear pallets

- Isolates empty pallet for safe, easy removal

- Protects workers from repetitive injuries

- Cost-effective vs. powered conveyor

Call the Mallard team for system design ideas, and let us help you improve case picking and order fulfillment productivity, all while protecting your team from the pain and expense of repetitive motion injuries.