Heavy-Duty Equipment Assembly Meets the Mighty Magnum Wheel

SOLUTIONS

FOR THE TOUGHEST APPLICATIONS

"*" indicates required fields

Magnum Wheel Pallet Flow Optimizes In-Process Assembly of Heavy-Duty Machinery

Gravity flow products are effective productivity tools for storage and retrieval of palletized, cased, and cartoned inventory, but before those products are packed and ready to ship, they have to be assembled. Small parts are often stored and staged for assembly in carton flow, but what about big parts? And, for that matter, what about really big parts? Don’t be intimidated by the question, we’ve got Magnum wheel pallet flow on our side and it’s the industry’s most durable, wheeled pallet flow.

To show just how extreme Magnum wheel pallet flow really is, check out a recent in-house Engineering Lab test that highlights not only a customized pallet flow lane configuration, but also the extreme lengths the Mallard engineers will go to ensure a perfect pallet flow solution.

Goal: Optimize manufacturing & assembly processes – minimize forklift travel, maximize speed & efficiency of parts delivery.

Inventory: Oversized, heavy-duty machinery parts

This interesting manufacturing challenge lead the Mallard team on a testing journey to perfect this pallet flow solution. Each piece of machinery was very large and there was a broad range of weights from 500 lbs. to over 2300 lbs. Finding a single pallet flow solution for this challenge would be, well, a challenge!

Pre-Test Preparation:

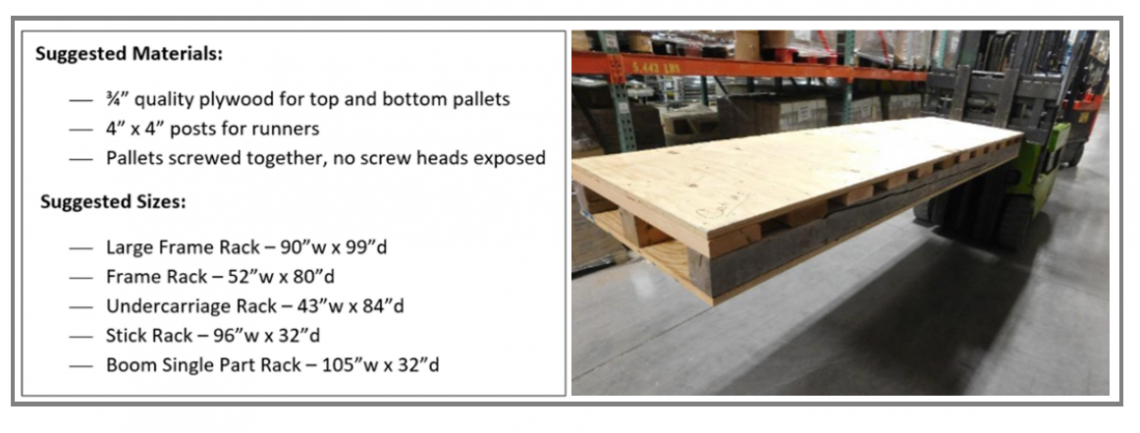

- Customized Captive Pallets

The team knew from past experience that the use of a captive pallet under each piece of inventory would ensure a more even weight distribution and superior wheel to pallet contact in the pallet flow lane. Because all of the inventory pieces were different sizes, we provided a spec sheet detailing the size and materials to create custom captive pallets for each type of inventory item.

Since the pallets were custom, we also included drawings marked to show pallet orientation (red) and the direction of flow for the pallets (green). These drawings help to ensure that the warehouse team would have a complete understanding of how to properly load the pallet flow lane.

Since the pallets were custom, we also included drawings marked to show pallet orientation (red) and the direction of flow for the pallets (green). These drawings help to ensure that the warehouse team would have a complete understanding of how to properly load the pallet flow lane.

In addition to understanding the pallet configuration for this unique lane design, we recommend forklift training for all pallet flow lane use. While pallet flow lanes are constructed to withstand rigorous daily use, abusive forklift loading interaction can cause costly downtime and repair expenses. For a quick forklift training refresher, visit our Properly Loading Pallet Flow Video.

The Tests:

- 4-rail & 3-rail Magnum Wheel Pallet Flow

- Drop-in Speed Controllers

- Bolt-on End Stops

Due to the enormous size of the inventory, we first designed a 4-rail pallet flow lane with drop-in speed controllers set 56” intervals to make contact with each pallet, no matter which size is being used.

As you can see in the video, at a pitch of 7/16” per foot, the pallets flowed very controlled down the lane. They also restarted after being left to sit and then extracted. As you can see at the end of each rail is a yellow bolt-on ramp stop to ensure that the pallet makes a slow and complete stop at the end of the lane and remains secured in the lane until extracted by the forklift.

As you can see in the video, at a pitch of 7/16” per foot, the pallets flowed very controlled down the lane. They also restarted after being left to sit and then extracted. As you can see at the end of each rail is a yellow bolt-on ramp stop to ensure that the pallet makes a slow and complete stop at the end of the lane and remains secured in the lane until extracted by the forklift.

With the customized captive pallets providing stability and uniformity we knew we had a good pallet flow solution, but the engineers tested a 3-rail pallet flow configuration to see if it would work just as well at a more economical price.

Again, as you can see from the video, the heavy-duty machinery parts flow just as well on the 3-rail Magnum wheel pallet flow configuration as they do on the 4-rail.

The Solution:

While the 4-rail system worked well… the 3-rail pallet flow lane worked just as well at a reduced price. Equipped with the speed controllers and ramp stops, and using the custom captive pallets, this is an optimized solution that will provide the needed efficiency and economies that our customer is seeking.

If you have a challenge… no matter how large… give us a call. We’ve got all this space now in our testing lab and we’re looking forward to our next big, or small, challenge!