Instantly Get Rid of Hundreds of Pounds… from Your Pallet Flow Lane

SOLUTIONS

FOR THE TOUGHEST APPLICATIONS

"*" indicates required fields

Weigh Less, Move Better! This may be a tagline for the latest diet craze… but what if we told you that by implementing this concept in your warehousing fulfillment operations you can increase pick rates and ensure worker safety?

Weigh Less, Move Better! This may be a tagline for the latest diet craze… but what if we told you that by implementing this concept in your warehousing fulfillment operations you can increase pick rates and ensure worker safety?

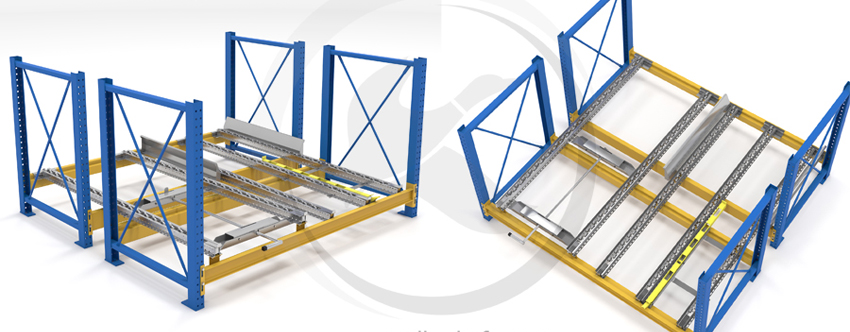

No, it’s not the latest HR Plan (it’s actually much easier to implement) and it’s much easier to stick to than a diet. We are talking about pallet flow rack separators, but not just any pallet separator – Mallard’s Case-Pick Pallet Separator CP-100 designed specifically for high density, pallet flow/ case-pick operations.

As one the most expensive areas of a warehouse, case-pick operations demand considerable attention – the process of picking the correct items in the most efficient way possible and in the least amount of time is absolutely critical. Within pallet flow case-pick applications, productivity can be hindered by unnecessary weight being exerted on the front pallet from rear pallets in the lane. Empty pallets must be removed to make room for stock replenishment but with the pressure of the rear pallets bearing down on the front pallet, it can be very difficult to lift and safely handle. We refer to that pressure as “back pressure” and it represents 6% of the combined weight of the rear load.

Ex: A 5-deep system with 2,500 lbs. loads = 600 lbs. additional weight applied to the front pallet

or .06 x 2,500 lbs. x 4 pallets (5 deep less empty first pallet) = 600 lbs. of pressure

A typical GMA style, empty wooden pallet, may weigh 30 – 70 lbs. depending on the size, wood and moisture conten. Now add-on 600 lbs. of pressure and you have a big potential slow down and injury problem on your line.

The Mallard testing lab has created a video demonstration to show the difference between removing an empty pallet with and without the case-pick pallet Separator.

The Mallard testing lab has created a video demonstration to show the difference between removing an empty pallet with and without the case-pick pallet Separator.

Check this out:

As a test perimeter, the engineers removed the empty pallet from the pallet flow lane into a narrow 36” “conveyor aisle” to mimic an actual high-density, case-pick application. Not only is this worker in danger of incurring a repeat motion injury but the tight aisle space leaves very little room to quickly maneuver the bulky pallet when the rear pallets are bearing down the flow lane. The pallet separator eliminates all of that added pressure, and with a simple foot tap the system is reset.

CP-100 Series Advantages

- Isolates front pallet/eliminates back pressure

- Provides more efficient order picking

- Allows safe removal of empty front pallet

- Ideal for 2-4 deep picking applications

- Can be used with all wheeled applications (skate wheel, Magnum wheel)

- Foot operated manual pallet release

Not every miracle cure is truly effective but we can guarantee that the case-pick pallet separator is the real deal. If you’d like us to design and video record a test of your pallet flow rack system give us a call today. We’ll set up an in-house test using your very own pallets, case-flow lanes and loads… You’ve got a lot to lose, but we mean that in a good way!

(800) 243-6694 (USA only)

(815) 624-9491

or info@mallardmfg.com