Mallard How To: Proper Loading & Unloading of Your Pallet Flow Rack System

SOLUTIONS

FOR THE TOUGHEST APPLICATIONS

"*" indicates required fields

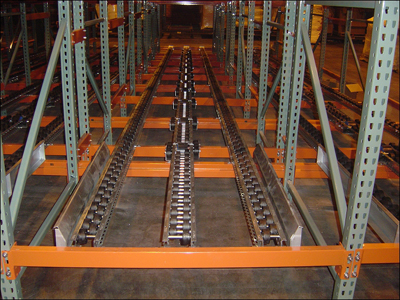

The New Year is the perfect time to check in with your warehouse team for a quick refresher course on the right way to load and unload your pallet flow rack system. Proper system interface ensures worker safety, better system performance, less equipment damage and enhanced productivity. The following guidelines and videos outline easy steps for pallet loading, unloading and clearing (plugging) a pallet hang up within the lane.

Split-Roller Pallet Flow – Mallard Manufacturing |

Mallard Magnum Wheel Pallet Flow with Entry Guides |

Guidelines

The video to the right shows proper loading/unloading procedures in action. The system shown is is a push-back pallet flow system however the process is the same for forklift approach to a traditional pallet flow lane.

Loading a Pallet Flow Rack System

- Position the fork truck squarely at the opening on the charge side of the system. Optional entry guides are mounted parallel and tight to flow rails with about ½”-1” clearance on both sides or are slightly tapered out at the first intermediate beam.

- Line up the fork truck with the entry guides or the center middle stringer of pallet with center rail.

- Enter the lane 2“- 3” above rollers. Do not launch pallets from the lift truck using forks.

- Tilt forks forward to place pallet onto lane, allowing pallet to roll away from fork truck to ensure it does not get hung up on entry guides. Avoid hitting the tips of the forks to the wheels.

- Note: If you notice a pallet with missing or broken bottom board DO NOT place it in the system.

- Back out clearing the end stop before turning.

- Position and load the subsequent pallets using the same process.

Unloading a Pallet Flow Rack System

- Enter the system squared to the face of the rack.

- Lift the front pallet to a level position just high enough to clear the front beam.

- Gently push the pallet back to bump the adjoining pallet which helps help start the forward flow and prevent any potential hang-ups of the subsequent pallets.

- Slowly extract the pallet.

- The remaining pallets will flow toward the aisle face.

- If the rear pallet(s) do not flow forward as the front pallet is removed, follow the steps for “Plugging the Pallet Flow” as demonstrated in our video below…

Just a Little Push

If your pallet flow rack system does not restart on its own to move pallets down the lane and repopulate the pick face position, then likely it just needs a little “push”. We call that Plugging the lane. Here is a video and the proper steps to take for restarting the pallets to flow forward. If plugging doesn’t work, then you may have debris or a broken pallet in the lane.

Plugging (restarting) a Pallet Flow Lane

- Lift the front pallet 1″ above the rollers.

- Firmly push or bump the rear pallets back into the lane, about 4″.

- Back out, extracting the front pallet and gently “plugging” the rear pallets forward.

- If this does not start the pallets freely moving within the system then reload the front pallet and do not unload until the system has been properly inspected and the blockage has been addressed.

Caution: Never climb into the live flow system for a stuck pallet.

For additional maintenance tips and pallet safety, see our blog: Maintenance Tips for Optimizing Pallet Flow Performance. And, if you have any additional questions regarding pallet flow usage or system design, call the gravity flow experts.