Roll Your Layer Picking into High Gear with Pallet Flow

SOLUTIONS

FOR THE TOUGHEST APPLICATIONS

"*" indicates required fields

Layer Pick Separators Updated to Fit Wheeled & Roller Pallet Flow

Case pick staging areas and mixing centers can benefit from layer picking, particularly for high-volume, high-SKU order fulfillment. Layer picking allows for one or more layers of cartons to be picked at a time to create custom, mixed “rainbow” pallets for order fulfillment.

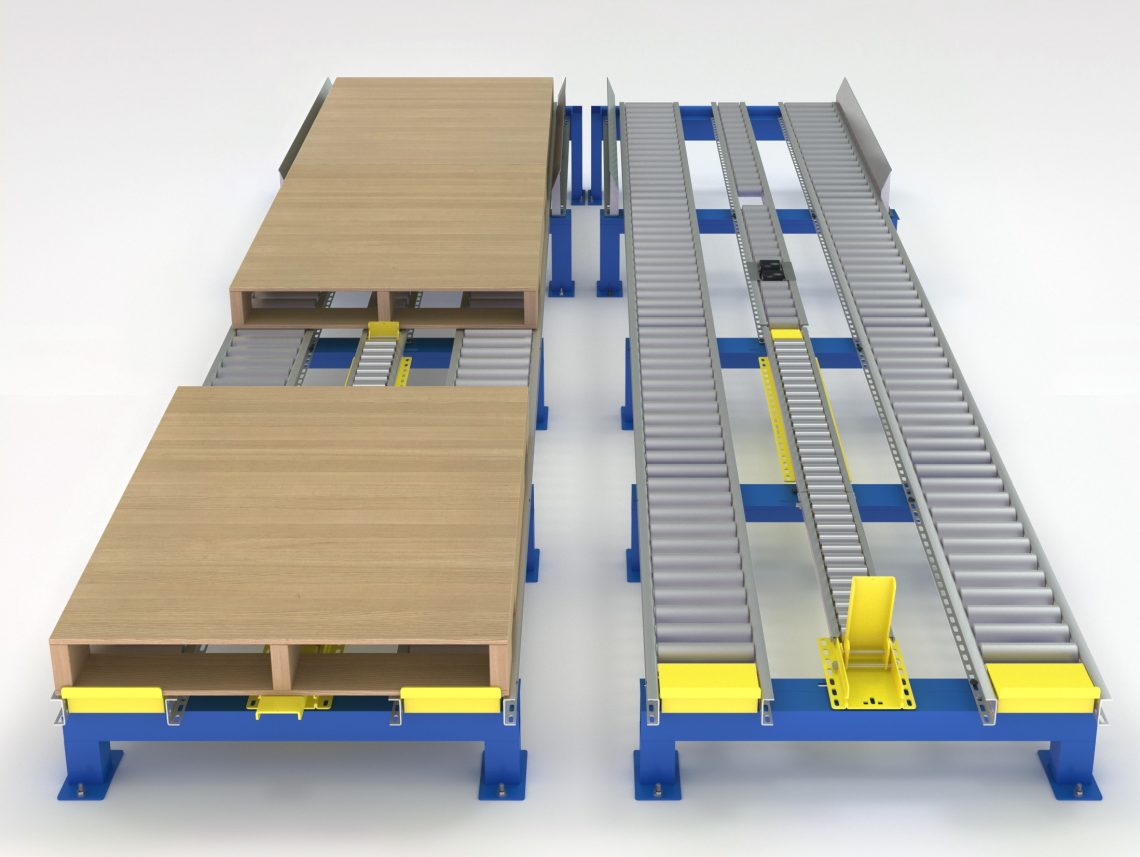

To further increase efficiencies, use floor-mounted pallet flow equipped with the layer pick separator vs. picking from floor-stacked pallets. Pallet flow provides ready reserve stock, automatically replenished pick face, and reduced traffic in the pick area to improve productivity. The layer pick separator is vital in removing the back pressure of the rear pallets from the front pallet and, in effect, isolating it for access by the layer pick device.

See how effectively this combo works with a layer picker in our 3D video.

Benefits of Pallet Flow with Layer Pick Separator

Benefits of Pallet Flow with Layer Pick Separator

- Increase productivity with easy empty pallet removal and automatically restocked pick face

- Improve warehouse safety & minimize traffic and congestion

- Works with Mallard wheeled and roller pallet flow systems

- Remove the empty pallet to trigger the automatic release of the rear pallets

- Minimal slope required

- Integrates easily with AGVs

As you can see from the video, the pallet separator holds the rear pallets back until the empty pallet is removed. This action automatically triggers the rear pallets to release and gently glide forward. When the front pallet position is filled, the LP separator engages to stop the rear pallets and hold them approximately 24” from the front pallet, again leaving sufficient room for the layer pick separator to grasp the cartons.

Layer Pick Separator Design Enhancements

Mallard recently updated our layer pick separator (LP Series) of products to include LP 400 and LP 401. There is now a layer pick separator for all our wheeled and roller pallet flow systems broadening the pallet types that can be used to include more than GMA-style wooden pallets. Now, just choose the best wheeled or roller system, and we have a pallet separator uniquely designed to meet that need.

Layer Pick Specifications

Both LP 400 & LP 401

- Select pallets 32”d – 48”d

- Choose pallets that are the same depth

- Add up to 24” to the lane to accommodate the layer-pick attachment

- Limit lane depth to 4 pallets behind the rear paddle

- Install floor-mount supports in the last two positions for proper function

- Check that the empty pallet is heavy enough to resist back pressure until removed

- Use only with floor-level pallet flow

LP 400

- Use with GMA-style & CHEP pallets

- Install alongside the center rail of a 3-rail lane

LP 401

- For use with plastic pallets (full roller transitions to 3-rail split-roller)

- Install in the center rail of the pallet flow lane

Layer Pick Separator LP 401

Choose the Layer Pick Separator that is Best for Your Needs

The LP 400 pallet separator is designed for GMA-style pallets and wheeled pallet flow. The LP 401 is designed for plastic pallets and non-GMA-style pallets that are typically going to be more consistent in full and split-roller pallet flow systems. If you need help configuring your pallet flow system for layer picking, please contact the Mallard team. Our gravity flow experts are available to ensure that your system meets your needs and helps you achieve your order-picking goals. Additionally, our Engineering Testing Lab can test the system design with your pallets and inventory to ensure that the pallets flow consistently, centered in the lane, and are free from hang-ups. Call us today.