Steady as She Goes for Metal and Wood on Full Roller Pallet Flow Rack

SOLUTIONS

FOR THE TOUGHEST APPLICATIONS

"*" indicates required fields

Creating Pallet Flow Rack for a Range of Pallet Materials?

Pallet flow racking lanes are designed by assessing the pallet specs, load weights, inventory dimensions, and warehouse conditions. From these details, our gravity flow rack experts can choose the right pallet flow product – wheeled or roller track – and begin to build a lane to meet the customer’s operational needs.

Occasionally, a customer requests that we find a single-lane design that will work across various pallet sizes, styles, and materials. This is a challenge on many levels because the primary goal of a pallet flow racking lane is consistent, safe, dependable flow, and varying weights and materials will flow differently. Heavy pallets need more control, as do pallets with little roller-to-pallet contact. However, lighter pallets and those with good surface contact require less intervention but maybe a different lane pitch. It’s all a matter of careful lane design.

Take a look at a recent test completed for a manufacturing customer. We tested three types of pallets — 2 wood and a pair of metal crates, with a slight weight variance. See how the Mallard in-house testing lab engineers configured a full roller lane as this customer’s go-to pallet flow lane.

Pallet Flow Rack System Design

|

Pallet Specs

|

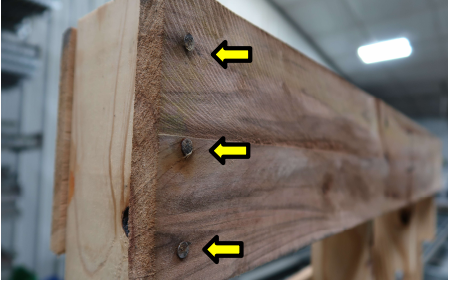

Pallets Tested – Arrows Indicate Direction of Flow

Pallet 1 |

Pallet 2 |

Metal Crate |

- Pallet 1 – Wooden pallet with four runners. Pallets have some warped boards.

- Pallet 2 – Wooden pallet with three cross boards. Pallets have warped boards, and one pallet has protruding nails.

- Metal crate – Two bottom runners with a 17″ gap separating them. Runners start at 5″ wide then narrow to 2″ wide. There is a bent runner.

Are You Flowing My Way?

As you can see in the test video, the wood pallet with the four bottom runners flows without any difficulty down the flow lane. The second wood pallet with cross boards has less surface area; however, it still maintains safe speed and mostly consistent flow. Lastly, the metal crates also flow at a safe rate and with consistency.

If a pallet does not restart after sitting in the lane, loading a new pallet in the lane will prompt the pallet to move or push back slightly as the forklift operator extracts a pallet. That’s called the plugging method. It is not uncommon for lanes designed for a range of pallet weights to require a little push now and again for lighter weight or poor quality pallets.

Cautionary Note Re. Pallet Condition

Cautionary Note Re. Pallet Condition

When it comes to warping, protruding nails, and bent or broken pallet components, these are pallet conditions that can cause pallet flow system hang-ups. We advise warehouse management to train staff or forklift operators to quickly scan pallets for severe pallet conditions that may cause a pallet to hang up or damage flow rack components. This is a critical consideration in deep lane systems. A few seconds of a scan may save you an abundance of downtime clearing a pallet lane.

Value-Added Services & Expert Advice

The gravity flow rack experts at Mallard are here to help you find the best pallet flow storage solution for your operation. Whether you need full pallet throughout or dynamic case picking from pallet applications, we will work with you to ensure your gravity flow system meets your expectations and is safe to operate. Call Mallard today to discuss your project needs or to schedule a pallet flow test in our lab.