Gravity Conveyor Rack

Harness the Power of Gravity Flow Rack at the IFDA Expo 2023 Are you picky when it comes to the best order-picking solutions for your food distribution warehouse? Good! So are we. Mallard’s gravity flow rack products offer a full spectrum of options and applications to meet a wide variety of food distribution needs. Our…

Read MoreHard Work & Dedication Lead to New Gravity Flow Processing Role & Promotion for Jessica Blaine There’s nothing quite as smooth as a well-engineered gravity flow solution, except perhaps the process that gets you there. At least, that’s what our newly appointed Scheduling Manager is determined to ensure. We’re pleased to announce Jessica Blaine’s promotion…

Read MoreWelcome Back to Mallard Meetup We begin the 2023 season of Mallard Manufacturing staff profiles with Order Processor (soon to be Engineer Tech) Curtia Sails… but you can call her “Tia.” Tia has only been with Mallard since the summer of 2022, but her zeal to learn and infectious personality have established her as the…

Read MoreTouch the Future with Gravity Flow Rack –See Us at PROMAT 2023! The calendar has flipped to a whole new year, and while March may seem a long way off, it will be here before you know it. That’s right, ProMat 2023 is right around the corner, and what better way to kick off the…

Read MoreManufacturing is all about precise details and processing. Each step along the way is critical and requires quality assurance to deliver superior gravity flow storage products. When you place an order with Mallard Manufacturing, it triggers our rigorous Total Quality Management (TQM) program, which checks and rechecks each order along the way to ensure that…

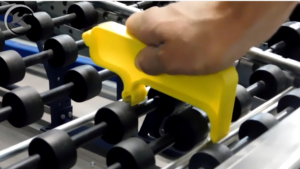

Read MoreOptimal Positioning for Dyna-Flo Carton Flow Entry Guides Snap to it! Everyone needs fast, accurate order picking, and one of the easiest and most cost-effective solutions is using carton flow rack and snap-on entry guides. Carton flow rack is a simple-to-use gravity flow storage solution that maximizes rack space into neat, orderly SKU lanes. Carton…

Read MoreWe never want our customers to be in distress, so we have spent years building up one of the most resourceful websites and instructional video libraries in the industry… but we’re not stopping there. To streamline your search for answers regarding all things gravity flow rack, we have created many ways to get just the…

Read MoreMallard Powder Coat – It’s More Than Just Pretty Gravity Flow Powder coating your gravity flow rack will brighten the aesthetics in your warehouse but more than that, it can help to protect your rack system components. Powder Coating Advantages Protective, prevents rusting Resistant to scratches, chipping and loosening Even coat, no running, nice finish…

Read MoreDoes it feel like we all took a little detour this past year? As the Mallard team looks back, we see that despite the challenges, we have a lot to show for the past 12 months. New products and innovations, new tools to help our customers and lots of good advice and demonstrations. By setting…

Read MoreLooking for the silver lining… There are so many ways to look back at the year that has been 2020. We started the year with great hope and optimism and proceeded to face unexpected challenges all year through. However, we have been able to witness something quite extraordinary this past year and it has guided…

Read More