Boost Productivity with Flexible, Portable Carton Flow Work Cells

If there’s one constant in manufacturing and process planning it’s the fact that things change, constantly. A company’s ability to respond to production shifts and assembly change-overs quickly, and with some level of “on-the-fly” flexibility, has a direct impact on production output and ROI.

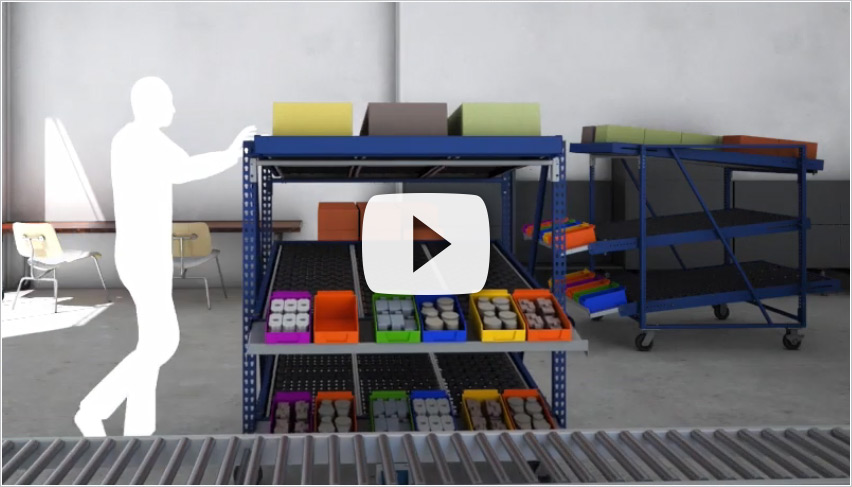

Mallard’s Carton Flow Work Cells are a cost-effective solution for handling process shifts. Carton flow work cells are mobile, ergonomic workstations designed to be flexible for easy SKU or shelf changes. Work cells can be moved where and when they’re needed for organized FIFO parts storage and assembly set-up. They are ideal for short-run manufacturing, light assembly, automotive and small-parts packaging.

Mallard Dyna-Flo, Dyna-Flo (HD) and Cart-Trak carton flow tracks can be integrated into the work cell… depending on carton specifications. Shelves are fully vertically adjustable to accommodate frequent SKU changes.

The carton flow work cell comes equipped with a steel-framed tow assembly for fast and easy relocation. Forklift operators can quickly transport work cells where needed vs. manually pushing the wheeled carts from station to station. Even better, the tow attachments can tow several work cells in a series.

Why Use Mallard Carton Flow Work Cells?

Advantages

- Increased Productivity – Work cell staging provides quick assembly change-overs supporting JIT manufacturing/production

- Greater Flexibility – Units are easily reconfigured for SKU and line changes

- Better organization – Keeps inventory of parts organized with FIFO stock rotation

- More ergonomic – vs. shelf or pallet storage; easy access to parts from carton flow and tilt tray

Specifications

- Widths – 32″, 48″, 58” and 70” clear

- Depths – to 58”

- Height – 84” posts/standard

- Finish – blue standard, contact us re. additional color options

Carton Flow Accessories Optimize Throughput

Depending on your inventory specifications, there are several unique and customizable carton flow accessories that can enhance the functionality of your mobile carton flow work cell. Snap-on entry guides and dividers are optional accessories that will help keep inventory tidy in the lane and aid in quickly identifying SKUs for picking and replenishing.

In addition, tilt trays are available to attach to the pick-end of the cart to provide a more ergonomic picking process and improve product pick-face visibility. Tilt trays are customized to fit your specific carton flow application.

Optional Accessories

-Snap-on entry guides

-Full-lane dividers

-Tilt Tray

If you are looking for a flexible system to increase efficiencies in pick and assembly areas, give us a call and let us demonstrate the benefits of the mobile carton flow work cell… seeing is believing!