Which Way Do You Flow? Pallet Flow Rack Test Solves the Question

SOLUTIONS

FOR THE TOUGHEST APPLICATIONS

"*" indicates required fields

Engineering the various components of a pallet flow rack lane is a careful process and fundamental to its success. However, the type of pallet, pallet condition, and the pallet orientation all play pivotal roles in optimizing the effectiveness of the pallet flow rack system.

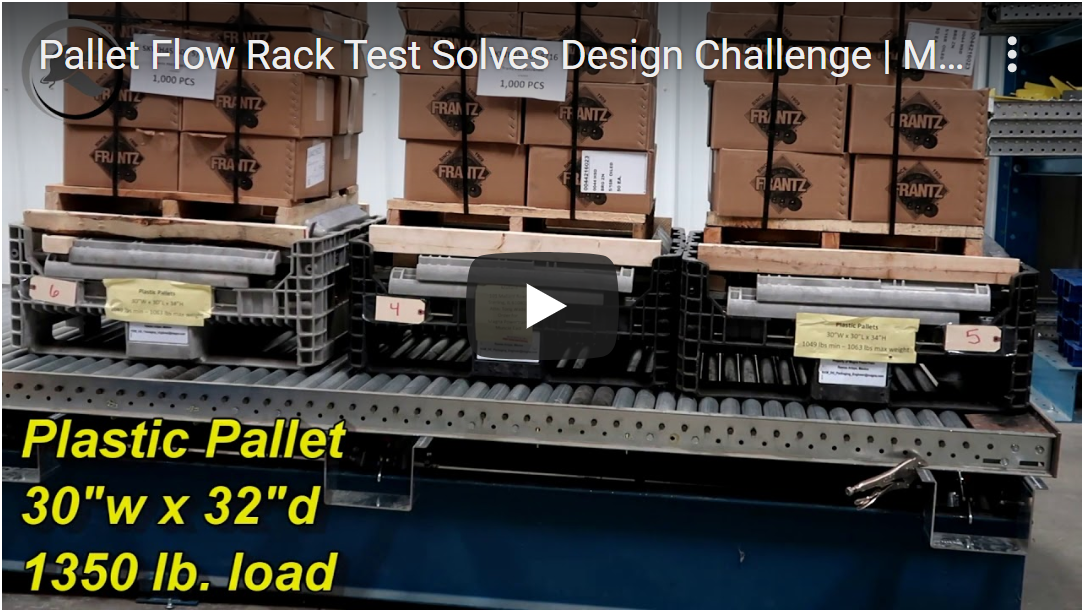

Following is a helpful test video from our Engineering Testing Lab that clearly shows how these elements come together to create the optimized inventory flow solution that you’re seeking.

Pallet Flow Test Criteria

Flow Lane Design

- Full-roller pallet flow on 2” centers

- Ultra-grip rollers with indirect mount speed controllers

- 7/16” per foot pitch over 30’ lane

Inventory Specs

- Load weights 1040 – 1360 lbs.

- Plastic pallets: 32” x 30”

- Wood pallets: 32” x 30”

Testing the Pallet Flow Lane

In this case, the customer supplied several different pallets, but all were the same size and the inventory weights didn’t vary dramatically. Essentially then, the test needed to confirm the pallet flow lane design and pallet orientation.

What do we mean by pallet orientation? At Mallard, we refer to pallet orientation as follows:

- The “easy way” (a.k.a. – right way) – bottom boards run parallel to the direction of flow.

- The “hard way” (a.k.a. – wrong way) – bottom boards run perpendicular to the direction of flow.

- Bi-directional – pallet can flow in either direction with max dimension dictating the direction of flow.

Plastic Pallet Test

Plastic Pallet Test

We first tested the plastic pallets using the “easy way” pallet orientation. The pallets have protruding feet on the bottom and this orientation keeps the feet from getting caught in the rollers.

The pallets flowed well in the lane with no hang-up issues. The ultra-grip rollers and undermount speed controllers worked together to control the flow and keep the pallets from surfing over the galvanized full rollers.

Wood Pallet Test

Wood Pallet Test

Next, we tested the wood pallets with similar positive results. We noticed that the pallets occasionally hung up as the pick face pallet was discharged from the lane. Implementing the plugging method (gentle nudge back before unloading the pallet) resumes proper flow.

We do caution about the potential for hang-ups due to broken and splintered pallet boards. We recommended that drivers quickly inspect pallets for dangling plastic wrap, broken boards, protruding nails, etc. before loading the pallet into the lane. For more on proper pallet loading, refer to our blog on the topic.

Result? Success!

Careful planning and testing helped us confirm that this pallet flow lane is best configured for this customer’s inventory. The pallet flow rack system installed will benefit their storage and picking operation with efficiency and simple to use and maintain equipment. What can the Mallard team do for you to help simplify and optimize your warehouse storage and picking operations? Give us a call and let’s put the power of gravity to work!